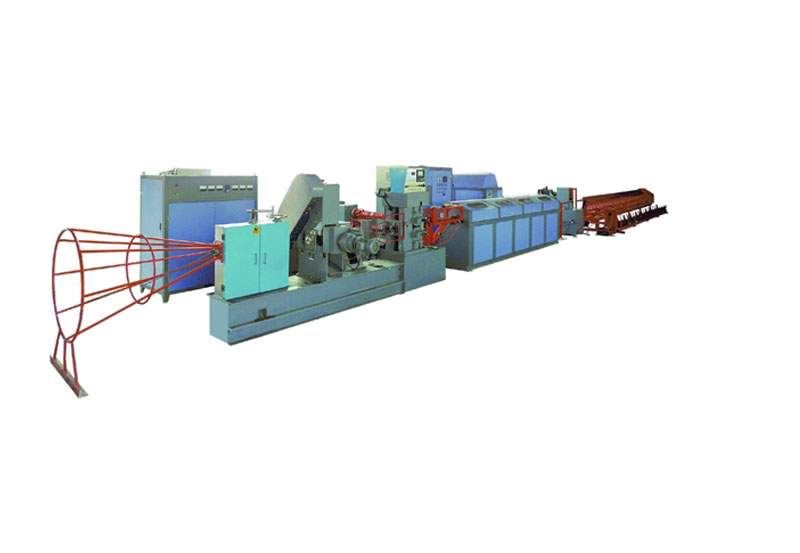

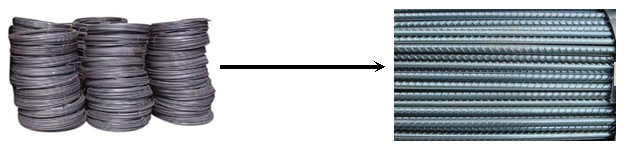

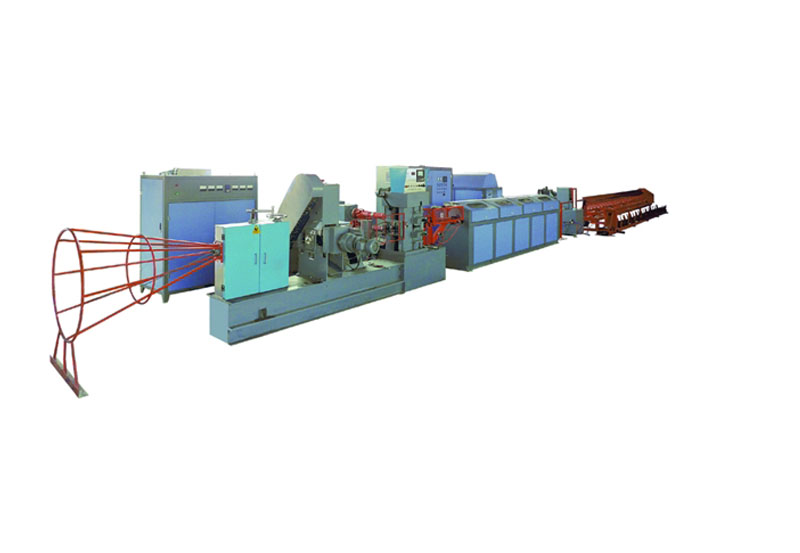

Our factory has successfully produced ZLM series of two - dimensional cold-rolled ribbed steel production line. The equipment can be 6.5 Phi Phi 14mm Q235 hot rolled coil steel, cold rolled into both sides of crescent ribbed bar, and completely solves the cold rolled ribbed bar with long plagued the elongation of substandard problem.

Two the equipment to produce cold-rolled ribbed steel, various technical indicators all over the hot rolled HRB400 (three steel), HRB500 (four steel) national standard, reinforced performance does not rebound, the extension does not drop, is an efficient alternative products grade three steel, three steel, and can save four in steel V Nb precious metal vanadium, niobium, titanium Ti.

The equipment has the advantages of convenient operation, from the line, steel rolling, strength control, extension control, cut to length, both sides of the blanking, automatic leveling, plate rolling line, to achieve full automation. The replacement of different steel bars does not require the replacement of the roller, the machine is only a simple adjustment, without lubrication powder, no cooling liquid, low production cost, is a set of loop type high efficiency cold rolling ribbed steel production line with two sides.

Structure characteristics:

- exclusive design:

The active mill is used in the main equipment, main mill and rolling mill in our factory, and the roll force distribution is balanced and the roll force is reduced by two times, so the roll life is twice as high as that of the same quality roller. (the main roller is used in the market, the other is passive roller, the main roller is too large and the roller is easy to be damaged)

Replacing different specifications of steel bars, no need to adjust the frame, guide material location will never be adjusted, and reduce the waste due to improper adjustment.

The roller adopts constant tension self locking method to solve the difficult problem of easy breaking and difficult fixing and dismounting of roller.

• drag motor drives, using a recognized energy-saving products, "inverter" using squirrel cage driving motor, the energy saving and failure rate to a minimum.

[use of synchronous loading design]: never adjust the roll center (I alone).

[use of double line frame and the whole line system design]: artificial line has become history, but also reduced due to downtime, threading, welding, resulting in inefficiencies.

[full digital control]: easy to operate, easy to change dimensions.

[descaling, cold rolling, transmission, guide material and cutting are made of rolling bearings]: long service life and good interchangeability.

[speed stepless adjustable, after welding round can also pass smoothly]: no waste.

The overall design of steel structures - []: no cement base pad can be produced.

[main engine gear adopts 20Crmnmo] material carburizing, quenching, grinding, noise, load strong, and equipped with water-cooled, self circulation cooling, 10 years long-term stable work, long service life.

[without external cooling]: random internal circulation system, no need to build pool - covers an area of money.

[guide material is made of wear-resistant material]: can reduce production costs.

Such as tungsten carbide alloy roller grinding, the service life of more than 10 thousand tons, can improve the quality of steel surface molding.

Brief introduction of unit configuration and performance:

This machine is a special equipment for the production of cold-rolled ribbed steel bars with two, the production line can be 6.5 Phi Phi 14mm Q235 hot rolled coil steel, cold rolled into both sides of crescent ribbed bars.

The complete set of equipment is composed of wire laying frame, whole wire cage, descaling machine, rolling mill, main mill, straightening, heating, temperature measuring, shearing, slideway, two side material receiving, pneumatic automatic pushing and take-up machine. The unit is designed according to the continuous working system, and the whole set of equipment is controlled by PLC system.

Here is a brief description of the structure and properties of each component:

(1) stringing frame;

The utility model has the function of ensuring the high-speed operation of the unit. The utility model is composed of a double discharge gun pipe, one is a work rack, the other is a reserve storage rack, and the other barrel can be preloaded when a line is placed. When working on the shelf after the end of the coil, the coil coil and the other end welding rack hanging round grinding, can continue to boot, then on another line to be pre frame material, this material can be improved by pre design to reduce the work efficiency after stop charging.

(2) whole wire cage;

The whole wire cage is welded by the threaded steel, and the funnel shape can change the steel bar from the annular to the spiral straight strip, so as to ensure that the steel bar enters the descaling machine before the descaling machine is basically straight and ensures the high-speed and reliable operation of the machine.

3) descaling machine

The descaling machine consists of 5 descaling wheels, and the new product has increased the electric pressure, the pressure reducing, the dustproof door, the inclined slideway, the oxide skin, the oxide skin collecting bag and the new concept of creating a clean dust-free scale.

(4) pay mill

The flat roll mill adopts active roller, adopts cooling system, uses Y2 energy-saving motor, adopts frequency converter to drive, and saves energy and efficiency.

(5) main mill

The new main rolling mill adopts fully sealed design, before pressure blocking and other problems are solved, the main gear box and a reversing gear box 2 for 1, remove the cross slider wearing parts, gear grinding smooth running without noise. Speed is greatly improved to 180200 M / min

(6) control panel;

The control system adopts PLC program control, touch screen display, can improve the operation stability and intuitive of the device, the touch screen will show the fault position, and can quickly and accurately find the fault point.

The length of the encoder is high, so as to improve the cutting accuracy.

Speed control: the main mill and the rolling mill adopt a knob, and the operation is simpler.

(7) heating cabinet

The heating equipment selection of the largest domestic several manufacturers for the user to choose, cabinet General specifications, also has high energy-saving heating equipment, the user can freely select, for energy-saving heating equipment vary greatly, the quality difference is large, to remind the user should be carefully selected.

(8) shearing

The new cut by servo I plant self-developed flying shear, imported servo motor, improve the reliability of the flying shear, improve the cutting precision, when accelerating or decelerating reinforced shear length and uniform shear is basically the same, low power, fast response, with industry leading level.

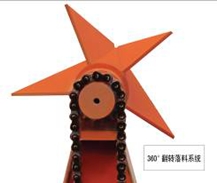

(9) 360 degree flip blanking chute system

The system adopts (A, B, C,, D, A) double cycle operation mode, the blanking rack adopts 360 degree rotation design, without clamping, avoiding the defects of regular adjustment and blanking.

(10) arranging blanking system;

With the original material feeding system, steel cut back rack will automatically move to the left or right, reinforced falling position not in a place, to effectively reduce the cross reinforced artificial to straight, but also can reduce the binding due to temperature difference reinforced uneven quality.

(11) receiving system

The double material rack (left and right) meets the material, the steel bar is cut off, and then falls from the turning plate, and then slides onto the inclined plane cable frame to slide into the U type material receiving device to store, so as to effectively improve work efficiency.

(12) leveling device

The steel bars fall into the aggregate rack, the length is not uniform, and they need to be pushed flat. I design a pneumatic automatic flat pushing device, which can replace manual pushing to eliminate unsafe hidden trouble, and how many roots can be pushed once

|

Product name

|

Company

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

|

Model

|

|

LMD10-9A

|

LMD12-10B

|

LMD12-10C

|

LMS12-10A

|

LMS12-10B

|

LMS16-14C

|

|

Diameter of base metal

|

mm

|

φ6-10

|

φ6-12

|

φ6-12

|

φ6-12

|

φ6-12

|

φ6-14

|

|

Diameter of finished product

|

mm

|

φ5-9

|

φ5-11

|

φ5-11

|

φ5-11

|

φ5-11

|

φ5-13

|

|

Roll line speed

|

m/min

|

120

|

150

|

180

|

150

|

180

|

200

|

|

Predetermined length

|

m

|

1~99

|

1~99

|

1~99

|

1~99

|

1~99

|

1~99

|

|

Length of chute

|

m

|

6~12

|

6~12

|

6~12

|

6~12

|

6~12

|

6~12

|

|

Blanking direction

|

|

Single direction blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

|

Blanking sliding mode

|

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

|

Row spacing

|

mm

|

Accessories 5~20

|

|

Two times aggregate length

|

m

|

Matching length 6~12

|

|

Aggregate flattening method

|

|

Pneumatic automatic flat pushing

|

|

Adjust speed

|

|

Adjust speed

|

frequency conversion

|

frequency conversion

|

Frequency conversion

|

Frequency conversion

|

Frequency conversion

|

|

control mode

|

|

text+PLC

|

text+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

|

Cutting error

|

mm

|

±4

|

±2

|

±2

|

±2

|

±2

|

±2

|

|

Host power

|

KW

|

75KW

|

90KW

|

132KW

|

75KW+90KW

|

90KW+110KW

|

110KW+132KW

|

|

heating power

|

KW

|

300

|

400(500)

|

500(600)

|

500

|

600

|

800

|

|

Total power

|

KW

|

400

|

500

|

650

|

670

|

800

|

1050

|

|

Total weight (approx.)

|

Kg

|

6000

|

8000

|

14000

|

9000

|

16000

|

20000

|

|

Work area (including line release, minimum)

|

Length * width(m)

|

40×5×6

|

50×5×6

|

50×5×6

|

50×5×6

|

55×5×6

|

70×5×6

|

|

Stringing frame

|

|

Dual set

|

|

Line regulator

|

|

Accessories

|

|

rolling mill

|

|

Up sync compression

|

Electric automatic tuning

|

Electric automatic tuning

|

Electric automatic centering

|

Electric automatic centering

|

Electric automatic centering

|

|

Rolling times

|

|

2

|

2

|

2

|

2

|

2

|

2

|

|

Roll size

|

mm

|

Active millφ228

+Passive millφ155

|

Active mill228+Passive millφ210

|

Active millφ228+Passive millφ210

|

Active millφ228+Active millφ210

|

Active millφ228+Active millφ210

|

Main millφ228+Active millφ210

|

|

Straightening method

|

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

|

Take-up

|

|

Accessories

|

|

Φ6mReinforcement yield

|

Kg

|

1598kg/h

|

2000kg/h

|

2398kg/h

|

2000kg/h

|

2398kg/h

|

2660kg/h

|

|

Φ7mmReinforcement quantity

|

Kg

|

2170kg /h

|

2700Kg/h

|

3250kg/h

|

2700 kg/h

|

3250Kg/h

|

3620 kg/h

|

|

Φ8mReinforcement yield

|

Kg

|

2800kg /h

|

3555kg/h

|

4200kg/h

|

3555 kg/h

|

4200kg/h

|

4728 kg/h

|

|

Φ9mReinforcement yield

|

Kg

|

3500kg /h

|

4400Kg/h

|

5000kg/h

|

440Kg/h

|

5000kg/h

|

5988 kg/h

|

|

Φ10mmReinforcement quantity

|

Kg

|

|

5000kg/h

|

5500kg/h

|

5000kg/h

|

5500kg/h

|

6000 kg/h

|

|

Φ11mmReinforcement quantity

|

Kg

|

|

5500kg/h

|

6000kg/h

|

5500 kg/h

|

6000kg/h

|

7500 kg/h

|

|

Φ12mmReinforcement quantity

|

Kg

|

|

|

|

|

|

7000 kg/h

|

|

Φ13mmReinforcement quantity

|

Kg

|

|

|

|

|

|

8000 kg/h

|

|

Φ14mmReinforcement quantity

|

Kg

|

|

|

|

|

|

7000 kg/h

|

|

Φ15mmReinforcement quantity

|

Kg

|

|

|

|

|

|

8000 kg/h

|

|

Complete set of operators

|

People / Unit

|

3

|

4

|

4

|

4

|

4

|

4

|